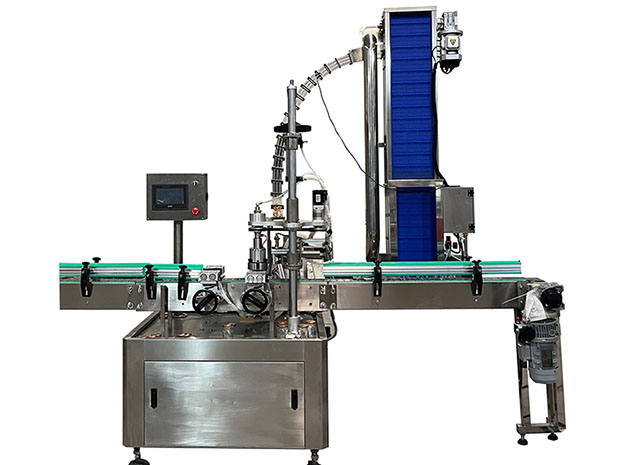

Bottle unscramblers are mainly used in the pre-filling process of bottling lines. Working in conjunction with conveyor belts, they stack, sort, and automatically and orderly feed bottles onto the conveyor belts of the next process, while also providing a buffering function. They are indispensable auxiliary equipment in automated production lines.

1.High degree of automation: Capable of continuously and stably processing large quantities of bottles, meeting the needs of high-speed production lines.

2.Stability: Stable operation, less prone to bottle jamming or tipping, ensuring continuous production line operation.

3.Wide applicability: Bottle unscramblers are typically designed with adjustable guides, rollers, or clamps to accommodate bottles of different shapes and sizes.

4.Low maintenance costs: Low failure rate, simple daily maintenance, easy to clean, meeting hygiene requirements in the food and other industries.

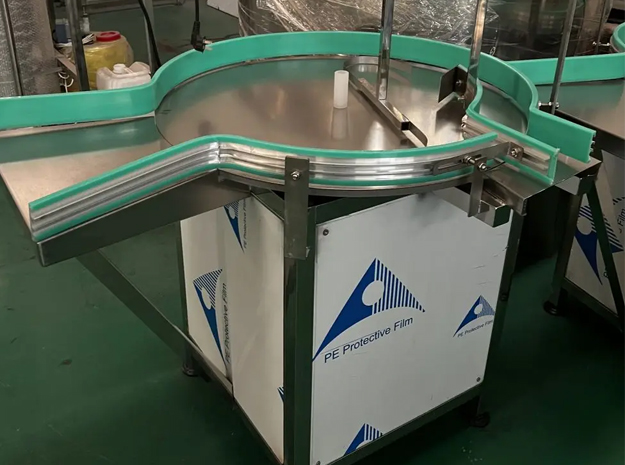

Suitable for bottles of various shapes, customization is supported.

| Applicable Specification | 10-1000ml |

| Applicable bottle diameter | φ10-φ100mm |

| Applicable bottle height | 55-300mm |

| Production capacity | 0-100Bottles/minute (speed adjustable) |

| Turntable diameter | Φ1000mm |

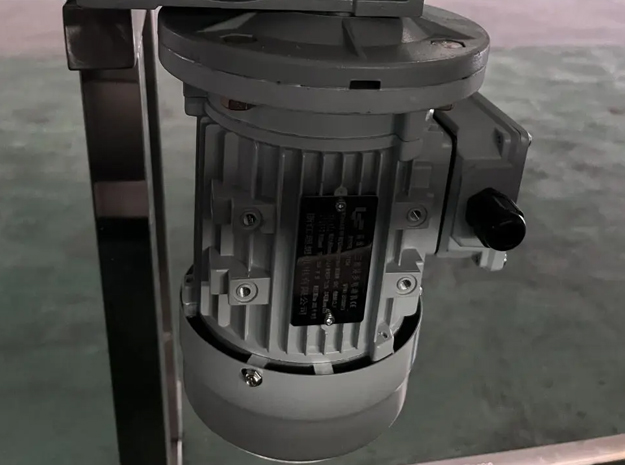

| Power supply | AC 220V 50HZ/0.2KW |

| Equipment weight | 80kg |